Things have been really pretty busy over the last few months. So much so, I'm going to split the work into 2 different posts so as not to over-face you or I.

Aberfeldy Distillery model kits

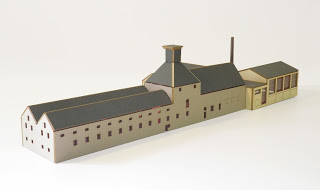

At the tail end of last year, I was approached by John Dewar & Sons to produce a model kit of their distillery in Aberfeldy. This meant a nice start to the year with a trip to Perthshire to see the distillery and get some photos. It's a traditional looking building, but with an extension added in the 70s to create a new Still House.

As well as the whopping 250 kits they ordered, when visiting the workshop the clients saw the Tinyment (metal model) and asked if I could also produce a small batch of metal models of the distillery for members of staff at Dewars. These were produced as built models, packaged in custom-made boxes.

The tree was made from birch plywood, and fabricated at the MAKlab. The components were cut using the CNC machine, with some detail also cut in using the CNC. I then laser-etched further detail (e.g. the place names) on the components. Great to be able to use these machines and processes - I've no idea how I'd have made it otherwise!

Aberfeldy Distillery model kits

At the tail end of last year, I was approached by John Dewar & Sons to produce a model kit of their distillery in Aberfeldy. This meant a nice start to the year with a trip to Perthshire to see the distillery and get some photos. It's a traditional looking building, but with an extension added in the 70s to create a new Still House.

As well as the whopping 250 kits they ordered, when visiting the workshop the clients saw the Tinyment (metal model) and asked if I could also produce a small batch of metal models of the distillery for members of staff at Dewars. These were produced as built models, packaged in custom-made boxes.

Lloyd's Register Technology Tree

At the start of May I was approached by a design company specialising in exhibition design with regards to work for an exhibition stand for Lloyd's Register - a register of ship classification established in 1760! After meeting with them at their base in Southampton, I was commissioned to design and build a 3.5m tall "Technology Tree" - a sculptural piece for inclusion in their exhibition stand. A little out of my normal remit, and I only had three and a half weeks to do it! In some ways, it was much like an enormous model kit - it had to be able to be shipped as compactly as possible, but assembled on site, and disassembled afterwards. The premise was that from the start in London, they've branched out all over the world - hence the branches had major ports that are LR's bases today. In addition, from the early days of shipping (represented by logos such as the Maltese Cross on the trunk), there is now new technologies and designs, represented in the designs on the upper branches.

|

| Maltese Cross, and classification 100A1. |

|

| The tree in situ at the trade show in Oslo. |

The tree was made from birch plywood, and fabricated at the MAKlab. The components were cut using the CNC machine, with some detail also cut in using the CNC. I then laser-etched further detail (e.g. the place names) on the components. Great to be able to use these machines and processes - I've no idea how I'd have made it otherwise!